Hydraulic test according to EN1074-1 and 2/EN 12266

Seat: 1.1PN, Body: 1.5PN

Closing torque test

Designed according to BS EN1074-1 and 2, EN1171

Face to face according to EN558 table 2 Basic Series 14/15, DINF4/F5

Flange drilling according to EN1092.2(ISO7005-2), PN10/16

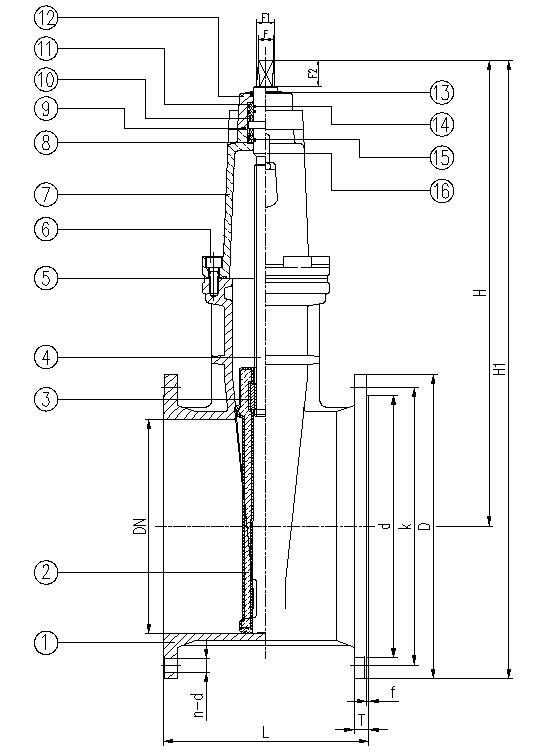

| 1 | Body | Ductile Iron | GJS-500-7 |

| 2 | Wedge | Ductile Iron | EPDM Encaps |

| 3 | Stem nut | Aluminum Bronze | C95210 |

| 4 | Stem | Stainless Steel | 2Cr13(420F) |

| 5 | Bonnet gasket | Rubber | EPDM |

| 6 | Bonnet bolt | Carbon Steel | Zinc plated |

| 7 | Bonnet | Ductile Iron | GJS-500-7 |

| 8 | Bushing | Aluminum Bronze | C95210 |

| 9 | O-ring | Rubber | NBR |

| 10 | Roller Bearing | Steel | 45# |

| 11 | Bushing | Aluminum Bronze | C95210 |

| 12 | Gland | Ductile Iron | GJS-500-7 |

| 13 | Dust seal | Rubber | EPDM |

| 14 | O-ring | Rubber | NBR |

| 15 | O-ring | Rubber | NBR |

| 16 | Eyebolts | Carbon Steel | Zinc plated |

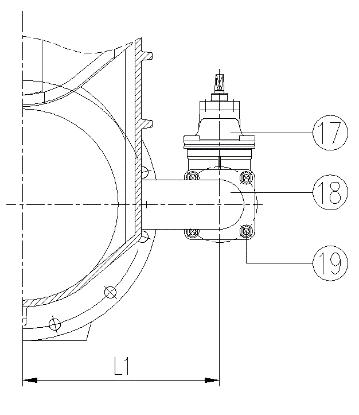

| 17 | Bypass valve | Ductile Iron | GJS-500-7 |

| 18 | Bypass pipe | Ductile Iron | GJS-500-7 |

| 19 | Fasteners | Carbon Steel | Zinc plated |

| BETTA ref. no. |

DN mm |

L mm |

H mm |

Flange Drilling to EN1092.2(ISO7005-2) mm |

H1 mm |

F mm |

F1 mm |

F2 mm |

Theoretical Weight/Kg |

||||||||||||

| D | K | d | T | n-d | f | ||||||||||||||||

| F4 | F5 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | ||||||||

| 350TZ49X1-10/16Q | 350 | 290 | 550 | 820 | 505 | 520 | 460 | 470 | 429 | 24.5 | 26.5 | 16-φ23 | 16-φ28 | 4 | 1073 | 27 |

32.2 |

52 | 195 | 205 | |

| 350TZ49X1-10/16QL | 1080 | 228 | 238 | ||||||||||||||||||

| 400TZ49X1-10/16Q | 400 | 310 | 600 | 920 | 565 | 580 | 515 | 525 | 480 | 489 | 24.5 | 28 | 16-φ28 | 16-φ31 | 4 | 1200 | 32 | 37.5 | 55 | 255 | 276 |

| 400TZ49X1-10/16QL | 1210 | 295 | 317 | ||||||||||||||||||

| 450TZ49X1-10/16Q | 450 | 330 | 650 | 990 | 615 | 640 | 565 | 585 | 530 | 548 | 25.5 | 30 | 20-φ28 | 20-φ31 | 4 | 1298 | 32 | 37.5 | 55 | 338 | 374 |

| 450TZ49X1-10/16QL | 1310 | 380 | 416 | ||||||||||||||||||

| 500TZ49X1-10/16Q | 500 | 350 | 700 | 1095 | 670 | 715 | 620 | 650 | 582 | 609 | 26.5 | 31.5 | 20-φ28 | 20-φ34 | 4 | 1430 | 36 | 41.8 | 58 | 457 | 497 |

| 500TZ49X1-10/16QL | 1455 | 525 | 565 | ||||||||||||||||||

| 600TZ49X1-10/16Q | 600 | 390 | 800 | 1260 | 780 | 840 | 725 | 770 | 682 | 720 | 30 | 36 | 20-φ31 | 20-φ37 | 5 | 1650 | 36 | 41.8 | 58 | 595 | 660 |

| 600TZ49X1-10/16QL | 1680 | 720 | 785 | ||||||||||||||||||

| 700TZ49X1-10/16Q | 700 | 430 | 900 | 1500 | 895 | 910 | 840 | 840 | 794 | 794 | 32.5 | 39.5 | 24-φ31 | 24-φ37 | 5 | 1950 | N/A | N/A | N/A | 815 | 840 |

| 700TZ49X1-10/16QL | 1955 | 999 | 1030 | ||||||||||||||||||

| 800TZ49X1-10/16Q | 800 | 470 | 1000 | 1685 | 1015 | 1025 | 950 | 950 | 901 | 901 | 35 | 43 | 24-φ34 | 24-φ41 | 5 | 2195 | N/A | N/A | N/A | 1086 | 1134 |

| 800TZ49X1-10/16QL | 2205 | 1338 | 1385 | ||||||||||||||||||