Hydraulic test according to AS2638.2-2011

Seat: 1.1PN, Body: 1.5PN

Closing torque test to AS2638.2 Table5.1

AS2638.2 Registration No. 25731

WaterMark Registration No. 25731

Designed and certified according to AS2638.2-2011

Face to face according to AS2638.2-2011

Flange drilling according to AS4087 Fig.B5/AS2129 Table D/E

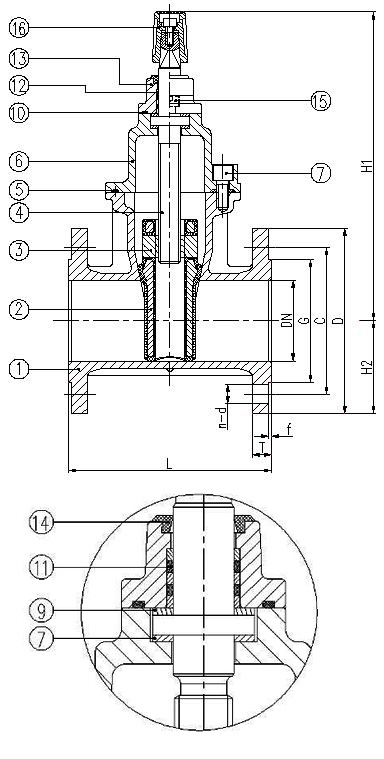

| 1 | Body | Ductile Iron | BS500-7 |

| 2 | Wedge | Ductile Iron | EPDM Encaps |

| 3 | Stem nut | Aluminum Bronze | C95210 |

| 4 | Stem | Stainless Steel | 1Cr17Ni2(431) |

| 5 | Bonnet gasket | Rubber | EPDM |

| 6 | Bonnet | Ductile Iron | BS500-7 |

| 7 | Bonnet bolt | Stainless Steel | 316(CF8M) |

| 8 | Washer | Plastic | POM |

| 9 | Wahser | Aluminum Bronze | C95210 |

| 10 | O-ring | Rubber | NBR |

| 11 | Stem seal | Rubber | NBR |

| 12 | Seal retainer | Plastic | POM |

| 13 | Gland | Stainless Steel | 316(CF8M) |

| 14 | Dust seal | Rubber | EPDM |

| 15 | Gland bolt | Stainless Steel | 316(CF8M) |

| 16 | Stem cap | Ductile Iron | BS500-7 |

| BETTA ref. no. |

DN mm |

L mm |

H1 mm |

Flange Drilling to AS4087 Fig.B5 & AS2129 Table D/Emm | |||||||||||||

| D | C | G | T | f | n-d |

Theoretical Weight/Kg |

|||||||||||

| AS 2129 |

AS 4087 |

AS 2129 |

AS 4087 |

AS 2129 |

AS 4087 | AS 2129 |

AS 4087 |

||||||||||

| TABLE-D | TABLE-E | TABLE-D | TABLE-E | TABLE-D | TABLE-E | ||||||||||||

| 50ASZ42X1-16Q | 50 | 178 | 260 | 150 | 114 | 90 | - | 17 | 19 | - | 1.6 | - | 4-φ18 | - | 12 | ||

| 65ASZ42X1-16Q | 65 | 190 | 270 | 165 | 127 | 103 | - | 17 | 19 | - | 1.6 | - | 4-φ18 | - | 15 | ||

| 80ASZ42X1-16Q | 80 | 203 | 310 | 185 | 146 | 122 | 19 | 18 | 1.6 | 3 | 4-φ18 | 22 | |||||

| 100ASZ42X1-16Q | 100 | 229 | 340 | 215 | 178 | 154 | 19 | 22 | 20 | 1.6 | 3 | 4-φ18 | 8-φ18 | 4-φ18 | 24 | ||

| 125ASZ42X1-16Q | 125 | 254 | 405 | 255 | 210 | 186 | - | 21 | 22 | - | 1.6 | - | 8-φ18 | - | 46 | ||

| 150ASZ42X1-16Q | 150 | 297 | 450 | 280 | 235 | 211 | 207 | 21 | 21 | 22 | 23 | 1.6 | 3 | 8-φ18 | 8-φ22 | 8-φ18 | 53 |

| 200ASZ42X1-16Q | 200 | 292 | 580 | 335 | 292 | 268 | 264 | 22 | 22 | 25 | 23 | 1.6 | 3 | 8-φ18 | 8-φ22 | 8-φ18 | 90 |

| 225ASZ42X1-16Q | 225 | 310 | 670 | 370 | 324 | - | 296 | - | 24 | - | 3 | 8-φ18 | 130 | ||||

| 250ASZ42X1-16Q | 250 | 330 | 670 | 405 | 356 | 328 | 25 | 24 | 1.6 | 3 | 8-φ22 | 12-φ22 | 8-φ22 | 134 | |||

| 300ASZ42X1-16Q | 300 | 356 | 780 | 455 | 406 | 378 | 374 | 376 | 25 | 29 | 30 | 1.6 | 4 | 12-φ22 | 12-φ26 | 12-φ22 | 180 |

| 350ASZ42X1-16Q | 350 | 381 | 830 | 525 | 470 | 438 | - | 29 | - | - | 1.6 | - | 12-φ26 | - | 216 | ||

| 375ASZ42X1-16Q | 375 | 381 | 935 | 550 | 495 | - | 463 | - | - | 33 | - | 4 | - | 12-φ26 | 278 | ||

| 400ASZ42X1-16Q | 400 | 406 | 1010 | 580 | 521 | 489 | 29 | 32 | - | 1.6 | - | 12-φ26 | - | 297 | |||